Laminated Glass

You are interested or you are having questions?

Laminated Glass

.

.

Prel-Lam is made of two or more pieces of glass permanently bonded together with one or more interlayers of PVB resin. During the laminating process, the multilayer glass is placed inside a pressurized autoclave, and then subjected to a combination of strong air pressure and high heat. The process ensures permanent adhesion of the different layers and allows for the creation of an integral unit with excellent optical quality.

CHARACTERISTICS

- Protects people and goods in the event of breakage, as the interlayer holds glass fragments together

- Meets safety glazing standards

- Blocks 99% of UV rays which cause fading and discolouration of interior coverings.

- Provides soundproofing that is superior to monolithic glass.

- Makes it possible to create unique glass designs with decorative interlayers such as Vanceva® (contact us for more information).

* Vanceva® is a trademark of Eastman Chemical Company.

Standards and certifications

CAN/CGSB 2 12.1 classe 1 et 2. – Safety or Laminated Glass,

ASTM C1172 – Standard Specification for Laminated Architectural Flat Glass,

CPSC 16 CFR 1201 classe 1 et 2 – Safety Standard for Architectural Glazing Materials

Choice of components

Types of glass

- Clear, ultraclear, tinted

- Low-e, reflective

Types of interlayers

PVB, ionoplast, polyurethane

Applications

Exterior Applications

- Sloped glazing

- Atriums and skylights

- Railings

- Storefronts exposed to sunlight

Interior Applications

- Jewellery showcases, museum or exhibition halls

- Glass partitions

Documentation

Sealant Compatibility: SentryGlas

Consult the tools section for all our documentation.

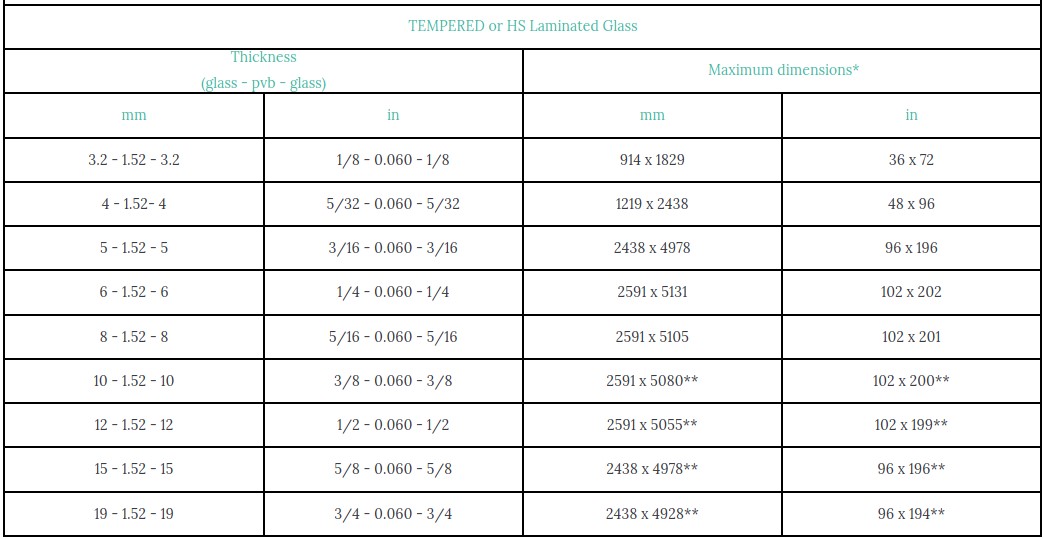

PRODUCTION CAPACITY

* Certain conditions apply, contact us for more information.

** Maximum weight of 318 kg (700 lb) per glass sheet and/or 680 kg (1500 lb) for the laminated glass.