In-Glass Printing

You are interested or you are having questions?

Silkscreened Glass

Prel-Design is glass that has had an opaque or translucent ceramic printed onto it through a silkscreen. During the printing process, the ceramic crosses only the open mesh of the screen which, as a stencil, reproduces the printed pattern. The ceramic is then fire-fused to the glass surface by heat treatment.

The multiple possibilities of colours and patterns allow to print:

- Geometric patterns

- Lettering

- Logos

- Pictures

- Etc.

CHARACTERISTICS

Standards and Certifications

ASTM C1036 – Flat glass, ASTM C1048- Heat-treated flat glass, CAN/CGSB 12.1 – Laminated or Tempered Safety Glass

Glass

Clear, ultraclear, tinted

Colours

Standard Opaque

White PC- 9918, Feather Grey PC-8800, Warm Grey PC-8933V, Medium Grey PC-8948, Charcoal PC- 9903, Wolf Grey PC-8194, Solar Grey PC- 9901, Black PC-9907, Spruce Shadow PC-8282, Evergreen PC- 9902, Lava Bronze PC-9905, Solar Bronze PC-9904, Blue Ford PC-9911, Morning Fog PC-10029.

Standard Translucent

Light Blue PC-7001, Light Green PC-7002, Charcoal PC- 7003, Yellow PC-7004, Clear PC- 7005, Azur PC- 7006, Cherry PC- 7007, Simulated Sandblast PC- 7008, Simulated Acid Etch PC- 7009

Glass makeup

Monolithic Glass

The ceramic coating is applied on face #2 on the glass.* The glass must be heat strengthened or tempered. It is not recommended to expose the ceramic coating to the elements. Use on an external face should be avoided.

Laminated Glass

The ceramic coating can be applied on face # 2, # 3 or # 4, of laminated glass.* For exterior use, all the glass plies should be heat strengthened or fully tempered.

Insulating Glass

The ceramic coating is applied on face #2 or #3 of insulated glass units.* The two lites that make up the unit should be heat strengthened or fully tempered.

*Certain conditions apply. Contact us for more information.

Applications

- Interior or exterior design

- Solar gain control

- Glare protection

- Occupant privacy solution

- Reduced light pollution

- Permanent printing of logos, text or any other geometric shapes on the glass

Documentation

Consult the tools section for all our documentation.

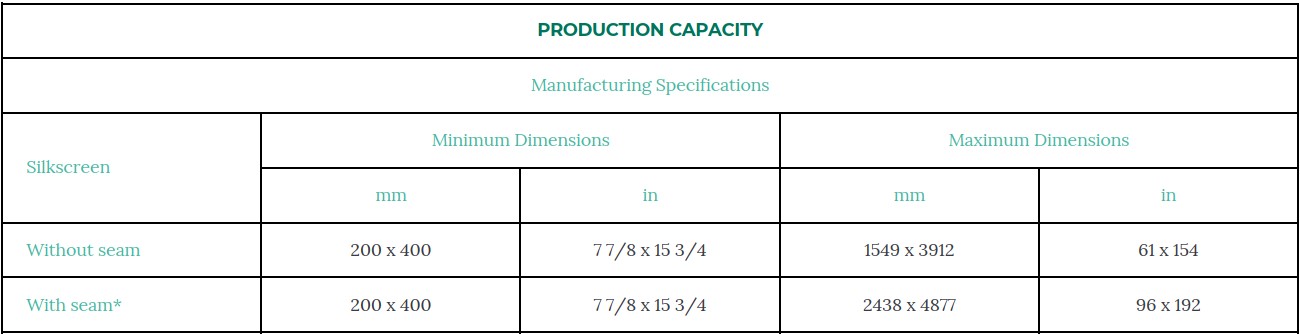

PRODUCTION CAPACITY

*Although all measurements are taken to minimize the appearance of a seam, it is sometimes noticeable once the glass has been screen-printed. The appearance of a seam depends on the complexity and density of the pattern. In some cases, it may be preferable to reduce the size of the glass lites.

Contact us for more information.