Heat-treated Glass

You are interested or you are having questions?

Tempered Glass

Heat-treated glass is heated in an oven at a high temperature and then cooled rapidly by blowing air onto both surfaces. The cooling process locks the glass surfaces in a state of compression while the core is in compensating tension. The compression of the tempered glass surface is greater than 10,000 psi (68.9 MPa), therefore meeting the ASTM C1048 standard.

CHARACTERISTICS

- Fully tempered glass is about four times stronger than annealed (non-tempered) glass of the same thickness.

- Glass breaks into small, dull fragments ensuring the protection of individuals.

- Provides increased resistance to wind and snow loads as well as high thermal stresses.

- Meets the requirements of Safety Glazing Standards.

- The glass maintains its colour, its chemical properties as well as light transmission properties after it has been heat-treated.

Standards and certifications

ANSI Z97.1 – Safety glazing materials used in buildings,

ASTM C1036 – Flat Glass, ASTM – C1048 – Heat-treated flat glass, CAN/CGSB 12.1 – Safety or laminated glass, CPSC 16 CFR- 1201 – Safety Standard for Architectural Glazing Materials

Types of glass

- Clear, ultraclear, tinted

- Low-e

- Reflective

Applications

Interior Applications

Railings, glass doors and partitions, shower doors and enclosures

Exterior Applications

- Insulated glass units and spandrel glass

- Skylights, storefronts

Documentation

Consult the tools section for all our documentation.

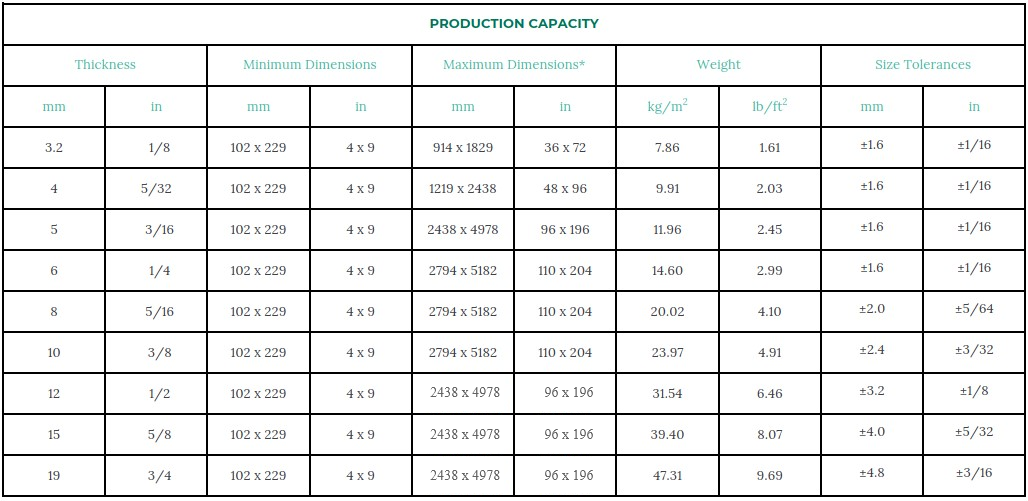

PRODUCTION CAPACITY

* 12mm maximum of 106pi² per glass

* 15mm maximum of 84.7pi² per glass

* 19mm maximum of 69.4pi² per glass.

*Certain conditions apply, contact us for more information.